Research Progress and Application Prospects of Transparent Ultra-High Molecular Weight Polyethylene (T-UHMWPE)

Research Progress and Application Prospects of Transparent Ultra-High Molecular Weight Polyethylene (T-UHMWPE)

Introduction

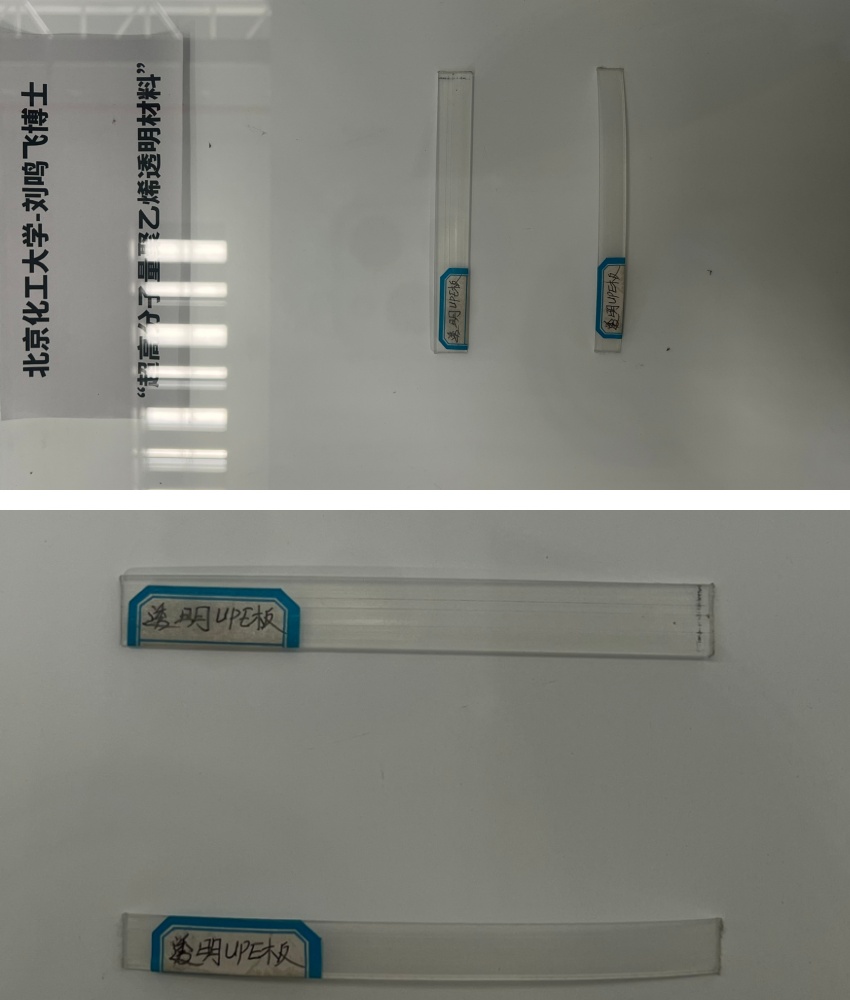

Our company has successfully developed a novel Transparent Ultra-High Molecular Weight Polyethylene (T-UHMWPE). After rigorous experimental validation and initial testing, this material demonstrates exceptional performance and vast application potential.

Product Advantages

T-UHMWPE offers significant advantages over traditional materials:

1. Unmatched Transparency: Achieves outstanding optical clarity while retaining the essential ultra-high molecular weight structure, enabling use in demanding high-transparency applications.

2. Superior Mechanical Strength: Possesses extremely high tensile strength and exceptional impact resistance, capable of performing under severe mechanical stress and in extreme environments.

3. Robust Chemical Stability: Exhibits excellent stability across diverse chemical media, providing strong corrosion resistance suitable for harsh industrial settings.

4. Enhanced Processability: Offers good adaptability to common processing techniques like injection molding and extrusion, enabling complex designs and manufacturing efficiency.

Application Fields

Current Applications

T-UHMWPE is already proving its value in several sectors:

1. Medical Devices: Its high clarity and biocompatibility make it ideal for transparent catheters, surgical instruments, and diagnostic equipment housings.

2. Optical Components: Superior optical transparency and chemical inertness suit it for high-precision lenses, optical fibers, light guides, and sensor windows.

3. Protective Equipment: Exceptional strength-to-weight ratio and impact absorption provide advantages in transparent ballistic shields (faceshields, visors), protective masks, and lightweight armor components.

Future Application Potential

The versatility of T-UHMWPE opens doors to new frontiers:

1. Aerospace: Lightweight nature, high strength, and environmental resistance offer potential for aircraft interior components, transparent structural panels, satellite components, and drone parts.

2. Advanced Electronics: Excellent electrical insulation and thermal stability present opportunities for high-performance insulating films, substrates, and thermally conductive yet electrically isolating components.

3. Automotive Innovation: High transparency combined with toughness and processability could revolutionize lightweight windows, sunroofs, headlight lenses, and durable interior elements.

Seeking Collaborative Partners

To accelerate the industrialization and broad adoption of T-UHMWPE, we actively seek global partnerships.

We invite industry leaders, researchers, and innovators across materials science, engineering design, manufacturing, and application development to collaborate with us.

Let’s explore together how T-UHMWPE can transform your products and create mutually successful advancements.