UHMWP

- Ultra-high molecular weight polyethylene is a linear thermoplastic engineering plastic. Its core characteristic is extremely high molecular weight, typically above 1.5 million. This ultra-long molecular chain structure endows it with a series of exceptionally superior properties, making it an ideal alternative to metals, other plastics, and even ceramics in many harsh operating conditions.

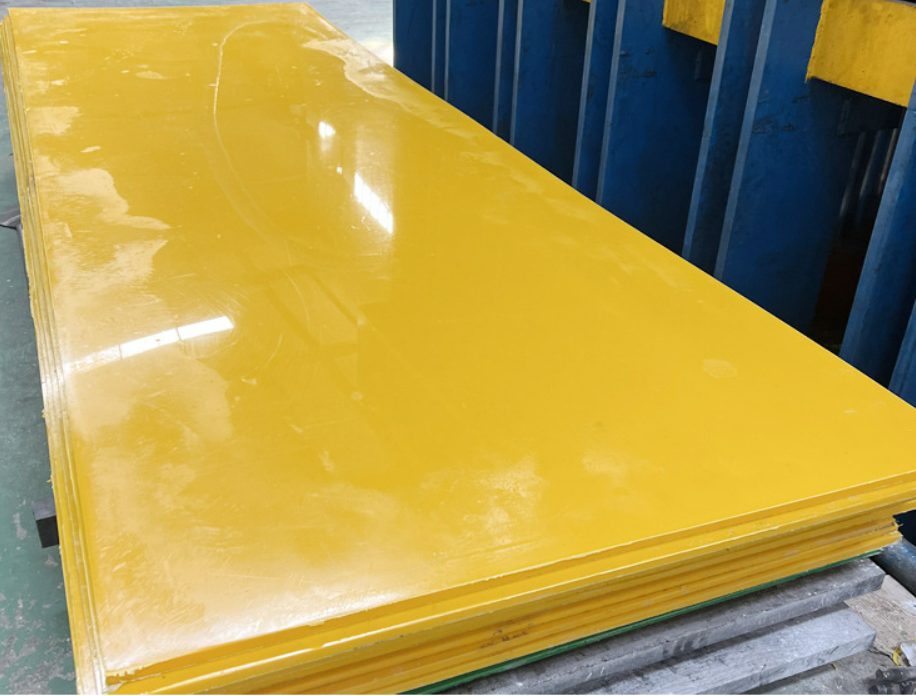

UHMWPE SHEET

Request InformationCompliance: GB/T 33521-2017 “Ultra-High Molecular Weight Polyethylene Sheets”

Product Details

I. Specifications & Technical Parameters

Compliance: GB/T 33521-2017 “Ultra-High Molecular Weight Polyethylene Sheets”

| Category | Parameter | Range/Value | Remarks |

|---|---|---|---|

| Dimensions | Thickness | 3mm – 200mm+ | Standard: 10–50mm; custom orders ≥200mm |

| Width | 1000mm – 2200mm | Custom widths via splicing/special equipment | |

| Length | 6000mm – 10000mm+ (custom) | Roll or sheet format | |

| Roll Width (Thin Sheets) | ≈1700mm (Thickness: 1–8mm) | – | |

| Molecular Props | Molecular Weight | 3–5+ Million | Higher = enhanced wear/impact resistance |

| Density | 0.935–0.945 g/cm³ | ~1/8 density of steel | |

| Physical Props | Abrasion Loss | Significantly < PA66/PTFE | 4–8× more wear-resistant than carbon steel |

| Dynamic Friction Coeff. | 0.07–0.2 | Excellent self-lubrication | |

| Static Friction Coeff. | <0.2 | – | |

| Impact Strength (23°C) | >150 kJ/m² (unnotched) | Highest among plastics; stable to -100°C | |

| Operating Temp. Range | -100°C to +80°C | Short-term exposure to 100°C | |

| Water Absorption | <0.01% | Negligible dimensional change | |

| Mechanical Props | Tensile Strength | 20–40 MPa | – |

| Flexural Strength | 25–50 MPa | – | |

| Hardness (Shore D) | 60–70 | Softer than metal yet more wear-resistant | |

| Tensile Modulus | 0.5–1.0 GPa | – | |

| Chemical Props | Chemical Resistance | Resists acids, alkalis, solvents | Excludes strong oxidizers (e.g., HNO₃/H₂SO₄ conc.) |

| Other Props | Food Safety | FDA/EU compliant | – |

| Electrical Insulation | Excellent | – | |

| UV Resistance | Optional (additive-enhanced) | – | |

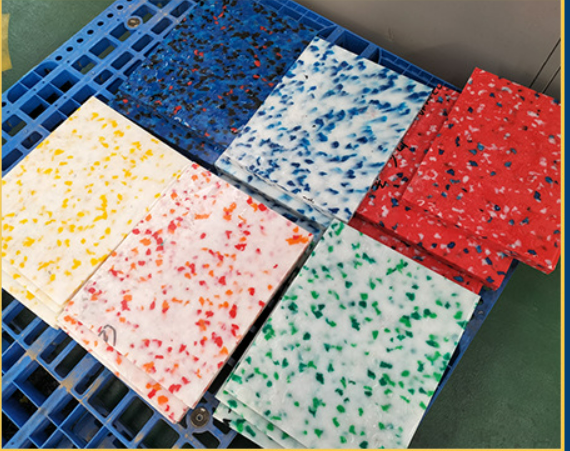

| Colors | White/Black/Green/Blue | Customizable | |

| Surface Finish | Smooth/Textured/Perforated | Textured for anti-slip; perforated for filtration |

II. Material Types & Customization

1. Material Composition

Base Resin: UHMWPE pure resin (MW 3M+), standard grade.

Modified Blends:

Wear/Friction Reduction: MoS₂, graphite, silicone oil additives.

Thermal Conductivity: Metal powder/carbon fiber fillers.

UV Resistance: Stabilizers for outdoor use.

Special Grades: Medical, cleanroom, antistatic (custom order).

2. Color Options

Pure White: Standard food-grade.

Black: UV-stabilized, dirt-masking.

Green/Blue: Industrial identification.

Custom colors (MOQ applies).

3. Surface Styles

Smooth: General-purpose.

Textured (Diamond/Striped): Anti-slip for chutes/platforms.

Perforated/Grilled: Filtration/weight reduction.

Chamfered Edges: Safety/compatibility.

Rolls: For curved applications (e.g., conveyor guides).

4. Molecular Weight Grades

3M MW: Cost-effective, standard wear resistance.

4–5M+ MW: Premium grade for extreme abrasion/impact (e.g., mining chutes, ballistic protection).