Rotational molding products

Ultra high molecular weight polyethylene boat buoy

Request InformationProduct Details

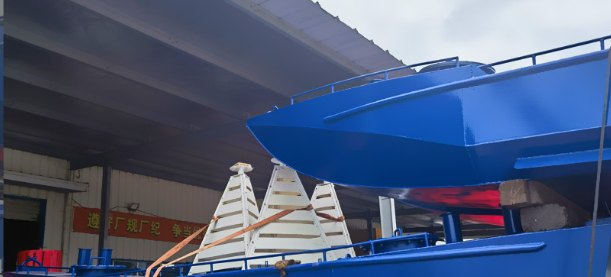

UHMWPE Boat-Shaped Navigation Buoy

Designed as visual aids for maritime navigation, these boat-shaped buoys are deployed at critical locations such as harbor entrances and channel turning points to assist vessel positioning and course alignment. Constructed from ultra-high-molecular-weight polyethylene (UHMWPE), they offer high wave resistance, watertight integrity, and long-term durability in marine environments.

Key Technical Features

Material Composition: UHMWPE with molecular weight ≥3.5 million g/mol, enhanced via chemical/physical cross-linking for improved creep resistance and environmental stress crack resistance (ESCR).

Maintenance-Free Coloring: Pigments are compounded into the base resin during extrusion, ensuring through-color consistency. Fade resistance exceeds 10 years under UV exposure without surface coatings.

Impact & Abrasion Resistance: Impact strength ≥160 kJ/m² (GB/T 21461); Rockwell hardness ≈40. Internal steel-plastic composite frame provides structural reinforcement while maintaining elastic recovery.

Low Surface Adhesion: Coefficient of friction ≈0.1–0.2 (dry). Smooth surface (Ra ≤0.082 μm per ISO 4287) minimizes biofouling; fouling is easily removed by high-pressure washing.

Environmental Stability: Resistant to seawater, acids (e.g., 36% HCl), alkalis (e.g., 40% NaOH), and UV degradation. Service life exceeds 30 years in temperate marine conditions.

Temperature Range: Operational from –200°C to +100°C, retaining ≥75% mechanical properties at cryogenic temperatures.

Hydrostatic Stability: Triple-layer hull design lowers center of gravity and increases metacentric height, providing superior roll stability compared to conventional steel buoys of similar displacement.

Sustainability: Fully recyclable. Surface restoration via polishing or abrasion cleaning restores appearance after extended service.

Material & Performance Specifications

| No. | Property | Test Standard / Condition | Result | Notes |

|---|---|---|---|---|

| 1 | Impact Strength | GB/T 21461 | ≥160 kJ/m² | |

| 2 | Tensile Strength | GB/T 1040 | ≥28 MPa | |

| 3 | Elongation at Break | GB/T 1040 | ≥350% | |

| 4 | Chemical Resistance | Immersion in 36% HCl / 40% NaOH | No visible degradation | After 30 days at 23°C |

| 5 | Non-Adhesion | 502 Super Glue adhesion test | No bonding | |

| 6 | Surface Roughness | ISO 4287 | Ra = 0.082 μm | |

| 7 | Accelerated Weathering | Xenon arc, 0.51 W/(m²·nm) @340 nm | No cracking/chalking | After 2000 hours |

| 8 | Color Compliance | GB 17381, IALA E-108 | Compliant | For navigational marking |

| 9 | Domestic Potable Water Safety | China Sanitary Standard for Drinking Water | Compliant | |

| 10 | International Food Contact | FDA 21 CFR 177.1520 | Compliant | |

| 11 | Collision Test | Simulated 500-ton vessel impact at 12 knots | No structural failure | Buoy remained operational |

| 12 | Tensile Load Test | 9-ton static mooring load | Elastic deformation only | No permanent set observed |

| 13 | Seam Weld Strength | GB/T 1040 (weld vs. base) | ≥95% of base material | Hot-plate welding process |