Industrial Products Series

Outrigger Pad

Request InformationProduct Details

Outrigger pads are high-performance engineering components designed to distribute ground pressure from hydraulic outriggers on heavy equipment—including cranes, concrete pumps, and aerial work platforms (AWPs). Manufactured from HDPE or UHMW-PE, they replace traditional steel or wooden pads with superior strength-to-weight ratios, corrosion resistance, and lifecycle efficiency.

1. Core Applications & Solutions

| Scenario | Pain Points | Solution | Case Example |

|---|---|---|---|

| Construction | Sinking/tilting on soft ground (silt/sand) | Load distribution via UHMW-PE pads | Crane stabilization on riverbanks |

| Ports/Docks | Saltwater corrosion of metal pads | 0% moisture absorption; corrosion resistance | 80% maintenance cost reduction |

| Mining/Quarrying | Rapid wear; heavy repositioning burden | UHMW-PE: 8× steel wear resistance; 70% lighter | Rapid deployment in rocky terrain |

| Bridge/Tunnel | Ground pressure damages structures | Custom sizes for precise load distribution | Foundation protection near piers |

| Emergency Ops | Slow deployment of wooden pads | Modular/foldable designs for stacking | Disaster response mobility |

2. Material Comparison: HDPE vs. UHMW-PE

| Property | HDPE | UHMW-PE | Advantage |

|---|---|---|---|

| Density (g/cm³) | 0.93–0.94 | 0.93–0.94 | 70% lighter than steel |

| Load Capacity | Standard | ↑ 50% vs. HDPE (same thickness) | Handles ultra-heavy equipment |

| Wear Resistance | High | 8× steel; 4× nylon | Ideal for abrasive surfaces |

| Impact Resistance | Good (−40°C to +80°C) | Excellent (−169°C to +80°C) | No brittle fracture in extreme cold |

| Cost Efficiency | Lower upfront cost | 3–5× longer lifespan | 60% lower lifecycle cost vs. steel |

3. Technical Specifications & Load Table

Max loads assume firm ground; soft ground reduces capacity by 30–50%. All dimensions customizable.

| Material | Length (mm) | Width (mm) | Thickness (mm) | Material Density (g/cm³) | Static Load (Tons) | Dynamic Load (Tons) | Max Rec. Load (3:1 Safety) (Tons) | Max Rec. Working Load (Tons) | Typical Weight (kg) | Applicable Scenarios and Notes |

|---|---|---|---|---|---|---|---|---|---|---|

| HDPE | 300 | 300 | 50 | 0.94~0.96 | 15 | 5 | 5 | — | — | — |

| HDPE | 400 | 400 | 50 | 0.94~0.96 | 25 | 8 | 8 | — | — | — |

| HDPE | 500 | 500 | 50 | 0.94~0.96 | 40 | 13 | 13 | — | — | — |

| HDPE | 600 | 600 | 30 | 0.94~0.96 | — | — | — | 100–200 | 7–8 | Light equipment, good ground, highly portable |

| HDPE | 600 | 600 | 40 | 0.94~0.96 | — | — | — | 150–250 | 9–10 | Light equipment, average ground |

| HDPE | 600 | 600 | 50 | 0.94~0.96 | 60 | 20 | 20 | — | — | — |

| HDPE | 800 | 800 | 50 | 0.94~0.96 | — | — | — | 200–350 | 15–16 | Common for medium-sized equipment |

| HDPE | 800 | 800 | 60 | 0.94~0.96 | — | — | — | 300–450 | 18–20 | Heavier equipment, improved stability |

| HDPE | 1000 | 1000 | 50 | 0.94~0.96 | — | — | — | 200–500 | 23–25 | Eisenburg Recommended (500-ton marked), heavier equipment |

| HDPE | 1000 | 1000 | 60 | 0.94~0.96 | — | — | — | 300–600 | 27–30 | Standard for heavy equipment |

| HDPE | 1000 | 1000 | 80 | 0.94~0.96 | — | — | — | 500–800 | 36–40 | Large heavy equipment, high load-bearing |

| HDPE | 1000 | 1000 | 100 | 0.94~0.96 | — | — | — | 600–1000 | 45–50 | Ultra-heavy equipment (e.g., large cranes) |

| HDPE | 1200 | 1200 | 80 | 0.94~0.96 | — | — | — | 600–900 | 52–58 | Large equipment + soft ground (mud/sand) |

| HDPE | 1200 | 1200 | 100 | 0.94~0.96 | — | — | — | 700–1200 | 65–72 | Extreme conditions (poor ground + ultra-heavy load) |

| UHMWPE | 500 | 500 | 100 | 0.93~0.94 | 70 | 23 | 23 | — | — | — |

| UHMWPE | 600 | 600 | 100 | 0.93~0.94 | 100 | 33 | 33 | — | — | — |

| UHMWPE | 800 | 800 | 50 | 0.93~0.94 | — | — | — | 300–600 | 15–16 | High-end: 50% higher load capacity vs. HDPE, improved wear/impact resistance |

| UHMWPE | 800 | 800 | 100 | 0.93~0.94 | 180 | 60 | 60 | — | — | — |

| UHMWPE | 1000 | 1000 | 50 | 0.93~0.94 | — | — | — | 300–700+ | 23–25 | Preferred for heavy loads, cost-effective (3–5× lifespan) |

| UHMWPE | 1000 | 1000 | 80 | 0.93~0.94 | — | — | — | 700–1200+ | 36–40 | Replaces HDPE 100mm, reduces weight |

| UHMWPE | 1000 | 1000 | 100 | 0.93~0.94 | 280 | 93 | 93 | — | — | — |

| UHMWPE | 1200 | 1200 | 100 | 0.93~0.94 | — | — | — | 1000+ | 65–72 | Ultra-extreme conditions (offshore platforms, mining) |

Notes:

• Custom sizes and thicknesses available.

• Safety margin includes 20% overload capacity.

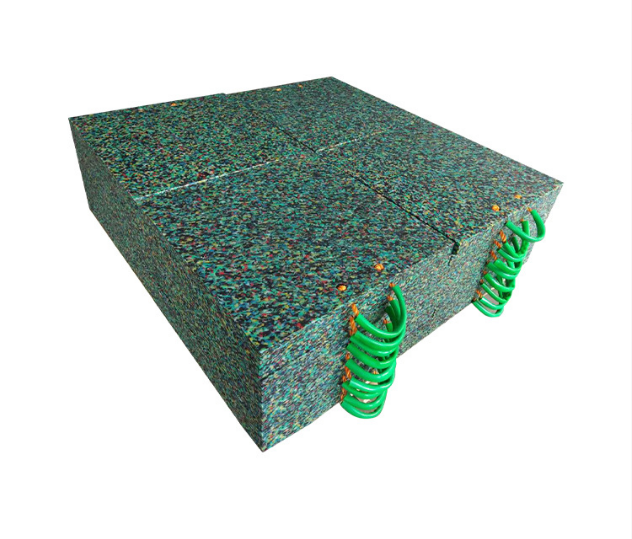

• Color options: Black (UV-stable), yellow, red, or natural.

4. Design Features & Safety

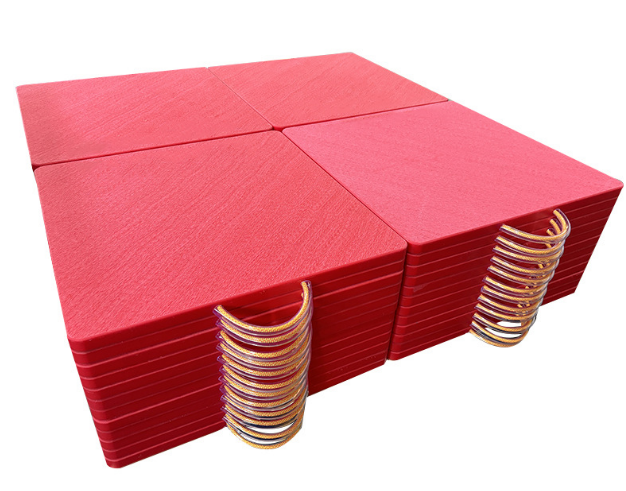

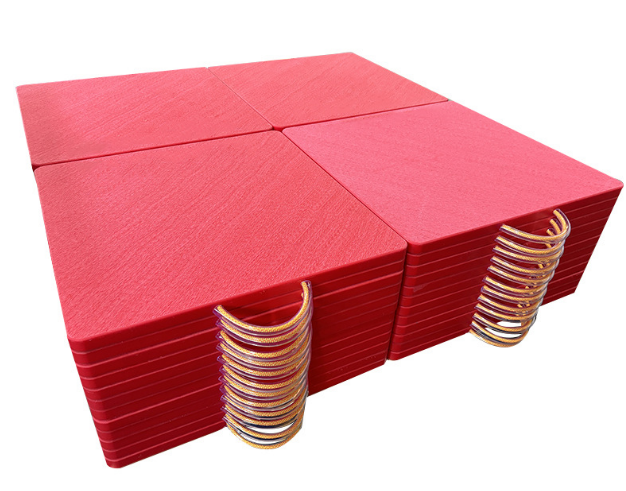

Anti-Slip Surface: Diamond or studded texture increases friction by 30% vs. smooth surfaces.

Structural Enhancements: Reinforced ribs, side slots for hook points, and stackable designs.

Critical Safety Properties:

Explosion-Proof: Non-sparking—certified for oil/gas sites.

Electrical Insulation: Non-conductive—ideal for power substations.

Non-Damaging: Protects asphalt, tiles, and sensitive surfaces.

5. Environmental & Economic Benefits

Eco-Compliance: 100% RoHS-certified and fully recyclable.

Zero Maintenance: No rust prevention, drying, or surface treatments required.

Cost Efficiency: 60% lower lifecycle cost vs. steel pads over 5 years.

Example: Steel pads require biannual replacement; UHMW-PE lasts 5+ years.

6. Manufacturing Standards & Customization

Materials: Virgin HDPE/UHMW-PE (no recycled content unless specified).

Testing: Compliant with ASTM/ISO load standards; custom prototypes available.

Customization Options:

Specialized dimensions/thicknesses (e.g., arc-shaped for cylindrical outriggers).

Branding or laser etching upon request.

7. Global Compliance & Best Practices

Usage Guidelines:

Always place pads on level, debris-free surfaces.

Avoid stacking more than 3 layers without engineering approval.

Inspect for cracks or deformation quarterly.

Industry Benchmarks:

Matches performance of Yale Cordage/Centurion UHMW-PE at competitive pricing.

Exceeds EN 1337-7 standards for load distribution.