Industrial Products Series

Wear-Resistant Liner

Request InformationProduct Details

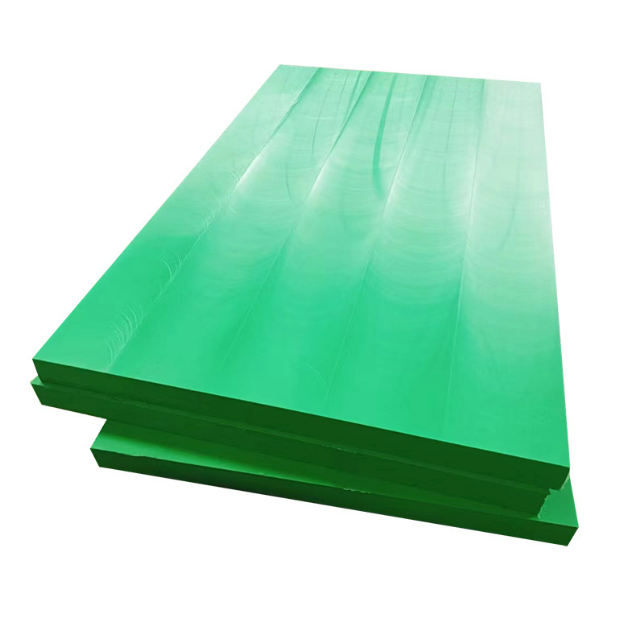

UHMWPE Wear-Resistant Liner

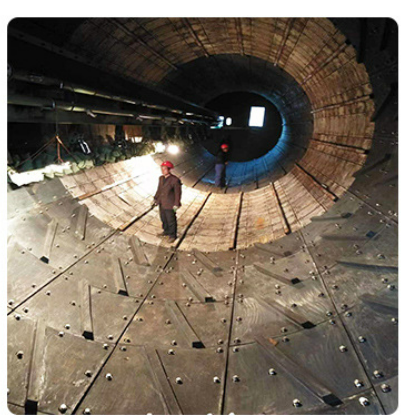

The UHMWPE wear-resistant liner redefines industrial wear protection through its lightweight, durable, chemically stable, and cost-effective performance. Whether resolving coal silo blockages, resisting abrasive ore flow, or ensuring food-grade safety, it delivers long-term reliability and operational efficiency. Choosing UHMWPE isn’t just a material decision—it’s an investment in sustainable, high-performance productivity.

Manufactured from ultra-high-molecular-weight polyethylene (UHMW-PE, molecular weight: 3–6 million), this engineered plastic sheet excels in wear resistance, impact toughness, self-lubrication, and chemical inertness. It outperforms traditional materials—including nylon, PTFE, stainless steel, and high-manganese steel—and is widely deployed across mining, power generation, construction, logistics, food processing, and chemical industries to solve challenges in material handling, storage, and equipment wear.

1. Core Advantages

Superior Wear Resistance & Extended Service Life

5–7× more wear-resistant than carbon steel and 4–5× better than stainless steel; slurry abrasion resistance of 70–120%.

Ideal for high-abrasion environments (e.g., coal, ore, cement), significantly reducing equipment replacement frequency and maintenance costs.

High Impact Resistance & Low-Temperature Adaptability

Maintains exceptional toughness from −40°C to +80°C, with notch impact strength of 80–170 kJ/m² (ASTM D256).

Absorbs impact energy, dampens vibration and noise—ideal for harsh climates or high-impact mining operations.

Self-Lubricating & Non-Stick Surface

Ultra-low coefficient of friction (0.07–0.11, comparable to ice), reducing flow resistance by up to 80% and eliminating bridging, adhesion, or blockages.

Ensures uninterrupted material flow in coal bunkers, grain silos, and chemical pipelines—no lubricants required.

Lightweight & Corrosion-Resistant

Density: 0.93–0.95 g/cm³ (≈1/8 that of steel)—simplifies installation and reduces structural load.

Resists acids, alkalis, seawater, and solvents; complies with FDA standards for direct food contact.

Maintenance-Free & Long-Term Stability

Water absorption <0.01%—unaffected by humidity; features anti-aging, flame-retardant, and anti-static properties.

Delivers a service life 3× longer than conventional materials.

2. Key Application Scenarios

| Industry | Application Scenarios | Solutions Provided |

|---|---|---|

| Power Industry | Coal bunker liners, conveying pipelines, dust removal systems | Prevents coal adhesion; reduces blockage rates by 90%; minimizes air cannon usage. |

| Mining Industry | Hoppers, chutes, vibrating screen liners, conveyor belts | Withstands ore impact/abrasion; extends equipment life 3–5×; cuts downtime. |

| Construction | Cement silos, concrete mixer liners, screw conveyors | Eliminates clumping; boosts conveying efficiency by 30%; lowers cleaning costs. |

| Logistics | Warehouse hoppers, sorting chutes, ship holds | Ensures smooth flow; reduces cargo damage and wall wear. |

| Food Industry | Grain tanks, feed conveyors (FDA-certified) | Prevents mold/adhesion; ensures hygiene and storage efficiency. |

| Chemical Industry | Acid/alkali tank linings, powder handling systems | Resists corrosion/buildup; mitigates contamination; prolongs equipment life. |

3. Technical Specifications

| Parameter | Value |

|---|---|

| Molecular Weight | 3–6 million |

| Density | 0.93–0.95 g/cm³ |

| Tensile Strength | ≥30 MPa |

| Coefficient of Friction | 0.07–0.11 |

| Operating Temperature | −40°C to +80°C |

| Water Absorption | <0.01% |

| Shore Hardness | D63–75 |

| Wear Resistance (ASTM D4060) | Exceeds nylon, PTFE, and metals |

4. Comparison with Traditional Materials

| Material | Wear Resistance | Impact Resistance | Friction Coefficient | Corrosion Resistance | Weight | Maintenance |

|---|---|---|---|---|---|---|

| UHMW-PE | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★☆ | Ultra-Light | None |

| Nylon (PA) | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | Light | Lubrication |

| Stainless Steel | ★★☆☆☆ | ★★★☆☆ | ★★☆☆☆ | ★★★★★ | Heavy | Rust-proofing |

| High-Manganese Steel | ★★★☆☆ | ★★★★☆ | ★★☆☆☆ | ★★☆☆☆ | Heavy | Replacement |

5. Installation & Maintenance

Installation Methods:

Bolting: Recommended for high-impact zones (e.g., ore chutes).

Thermal Welding: For seamless, sealed joints using compatible UHMW-PE welding rods.

Embedded Mounting: Ideal for conveyors or chutes requiring flush, smooth surfaces.

Maintenance:

No lubrication or special upkeep required; periodic bolt inspection suffices.

Surface scratches do not compromise performance; damaged sections can be locally replaced.

6. Value Proposition

Economic Benefits:

Extends equipment lifespan by 3×+, reduces unplanned downtime, and lowers spare parts inventory.

Lightweight design cuts transportation/installation costs and improves efficiency by up to 50%.

Environmental Benefits:

Eliminates need for lubricants; prevents product contamination; fully recyclable and eco-friendly.

Safety Benefits:

Anti-static and flame-retardant formulations reduce explosion risks in coal/chemical facilities.

Minimizes manual intervention in hazardous clearing operations—enhancing worker safety.

7. Service Commitment

Custom sizes, thicknesses (≥8 mm standard), and colors available—with full technical design support and installation guidance.

Includes a 3-year warranty, lifetime technical assistance, and rapid-response customer service.