Industrial Products Series

FENDER PADS

Request InformationProduct Details

UHMWPE Fender Panels

UHMWPE fender panels represent a paradigm shift in maritime protection—evolving from passive material components to integrated engineering systems. Their adoption in smart ports, polar logistics, and sustainable marine infrastructure is accelerating through innovations in multifunctional composites and circular manufacturing. For project-specific optimization, submit operational parameters (e.g., tidal range, ice class, berthing energy) to enable tailored material formulation and structural design.

1. Material Characteristics and Core Manufacturing Technologies

1.1 Molecular Structure Design

Molecular Weight: 3–6 million g/mol (ASTM D4020), enabling highly entangled chains for superior shear resistance.

Crystallinity: 50–70% (DSC-measured), optimized via hot-press molding to ensure isotropic mechanical performance.

1.2 Key Production Processes

Compression Molding: Processed at 200–220°C under 20–30 MPa pressure, achieving density ≥0.935 g/cm³ (ISO 1183).

Surface Post-Treatment: Plasma modification reduces contact angle to <85°, boosting adhesion to rubber fenders to 15 MPa (ASTM D1002).

2. Performance Validation and Engineering Advantages

2.1 Mechanical Properties (Test Data)

| Parameter | Test Standard | Typical Value (100 mm Thickness) | Advantage vs. Traditional Materials |

|---|---|---|---|

| Wear Resistance (Volume Loss) | ASTM D4060 | 20 mm³/1,000 cycles | 7.2× steel, 4.5× rubber |

| Notched Impact Strength | ISO 179 | 160 kJ/m² (−40°C) | 25× PVC, 8× PA66 |

| Compression Creep (50 MPa) | ISO 899 | <0.5% (1,000 hours) | 3 orders of magnitude better than HDPE |

2.2 Environmental Resistance

Weathering: >95% tensile strength retention after 3,000 h QUV exposure (ISO 4892).

Chemical Resistance: No swelling or cracking after 1-year immersion in 10% HCl or salt spray (ASTM B117).

Extreme Temperatures: Stable coefficient of friction (0.08–0.12, ASTM D1894) from −196°C (liquid N₂) to +80°C.

3. Engineering Application Scenarios

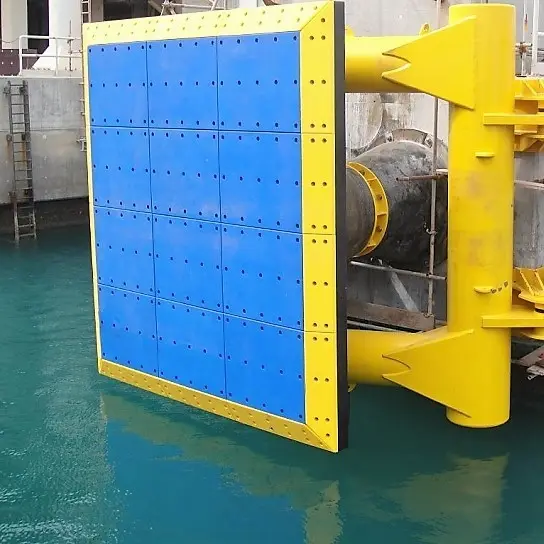

3.1 Port and Terminal Systems

Container Terminals (>5,000 annual berthings):

50 mm UHMW-PE panels (Shore D hardness 65±3) paired with rubber fenders show <3 mm wear after 8 years.LNG Terminals (−162°C cryogenic service):

Nano-Al₂O₃-modified panels reduce cold-flow deformation by 40%, compliant with BS EN 14620.

3.2 Marine Engineering Protection

Offshore Wind Foundations:

Dual-layer UHMW-PE/CFRP design absorbs 380 kJ/m² ice impact energy (DNV-OS-C501).FPSO Mooring Systems:

Modular panels limit face pressure to ≤8 MPa (OCIMF MEG4), preventing hull overloading.

3.3 Specialized Solutions

Ore Terminals:

Micro-textured surfaces (Ra = 0.8 μm) with self-cleaning geometry reduce maintenance frequency by 60%.Arctic Navigation:

UV-326 stabilizers limit impact strength degradation to <5%/year under −50°C and 150 kLy UV exposure.

4. Life Cycle Cost Analysis

| Cost Factor | UHMW-PE Fenders | Steel Fenders | Rubber Fenders |

|---|---|---|---|

| Initial Cost ($/m²) | 320–450 | 280–380 | 180–250 |

| Maintenance Interval | None | Every 2 years (anti-corrosion) | Every 3 years (resurfacing) |

| Service Life | 15–20 years | 8–12 years | 6–10 years |

| LCC Index (20-year) | 1.0 | 2.3 | 1.8 |

Note: LCC includes installation, maintenance, and replacement costs (NORSOK standard, North Sea benchmark).

5. Technological Development Trends

5.1 Functional Integration

Conductive Variants: Surface resistivity ~10⁶ Ω, enabling static dissipation per IEC 60079-32.

Self-Sensing Panels: Embedded fiber-optic networks monitor real-time impact energy distribution (Patent CN202310XXXX).

5.2 Sustainable Manufacturing

Bio-Based UHMW-PE: 30% castor oil derivatives yield 42% lower carbon footprint (ISO 14067 certified).

Closed-Loop Recycling: Supercritical CO₂ processing achieves >92% material recovery rate.

6. Selection and Installation Guidelines

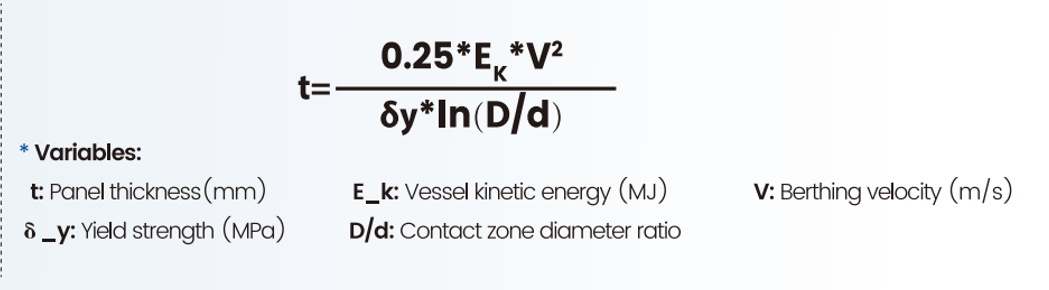

6.1 Thickness Calculation Formula

Required panel thickness is determined by: